Corrosion of brass in water distribution systems

Brass, a common alloy of copper and zinc with lesser amounts of lead and tin, is ubiquitous in water distribution systems. Because the zinc component is relatively easily lost to the water, brass corrosion is ever present and can lead to serious failures in of system components. Moreover, as the brass corrodes it releases its lead component. This process is the dominant source of lead in drinking water in systems that do not have lead service lines.

Types of brass - brass is an incredibly versatile alloy and is found in a nearly countless array of types and compositions (see table of brasses commonly used in drinking water applications). This array is traditionally divided into alpha brasses -- those having a single type of crystal and with continuous Cu-Zn solid solution up to about 35 % zinc -- and duplex brasses -- those having a mixture of alpha grains and higher-zinc beta grains. Therefore alpha brasses are one-phase alloys whereas duplex brasses are two-phase.

Brass corrosion scales - Brass and copper share some of the same minerals in their corrosion products, chiefly the Cu oxides cuprite and tenorite and the carbonate malachite. Also common on brass are a series of Cu sulfates of different hydration states and even the Cu chloride atacamite.

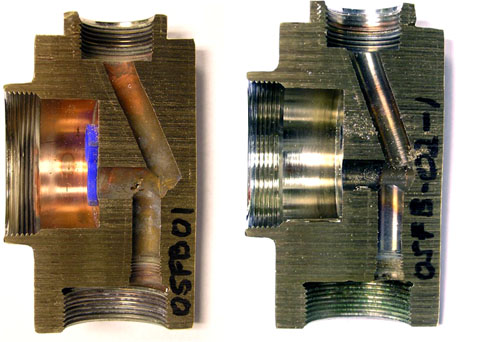

Dezincification - of the two main constituents in the alloy, copper and zinc, zinc is appreciably more soluble. Consequently it is leached faster than copper, leaving behind a porous, copper-rich metal that is prone to failure. All brasses dezincify over time, but some are more resistant. It is generally, although not universally, believed that higher Zn contents of brass lead to faster dezincification. Small amounts of P or As are sometimes added to the brass to retard dezincification, especially in brasses for marine applications.